Studio Tour

Welcome to Myrth Ceramics

Myrth is located in a quaint brick building in the vibrant heart of Somerville’s Union Square, and it’s the home to both our manufacturing studio as well as our retail shop Myrth Shop. Update: Myrth has moved to Providence in early 2024. We’ll share our new factory soon, until then this is still a great BTS peek of how we make our ceramics.

Here Eric and Abby collaboratively design and hand-craft all of our ceramics. We produce batches of our wares using three manufacturing methods. Our vases are hand-thrown on the potter’s wheel, our plates and bowls are jiggered, and our drinkware is slip cast. We do take care to preserve signs of our handcraft as we create our products so that each vessels or dish is still unique.

Let’s explore the studio through the different manufacturing process we employ.

Jiggering

Jiggering is a forming method where clay is hand-thrown into a spinning plaster mold, and then the shape is refined and finished with a metal blade on a pivoting arm. This is how we make all of our plates and bowls. You’ll see two types of molds below. Plates are made upside down with their foot facing up, and bowls are made right side up. This orientation helps the clay dry efficiently. We produce our wares in batches of around 25 items and typically make two different types of plates/bowls in a work day.

Above you’ll see the full process of forming our plates on the jigger.

Slip Casting

To make all of our drinkware vessels + platters we use a process called slip casting. In this process we pour liquid clay into plaster molds where it sets. The plaster slowly draws the moisture from the liquid clay until a firm shell is formed in the mold cavity. When the slip has cured to our desired wall thickness we pour out the excess slip for reuse later. Mugs and Swigs are removed them from the molds when they are firm enough to handle usually a few hours later. We finish our vessels by trimming off the excess clay on top and around the seams.

Wheel Throwing

The most classic ceramic forming method is wheel throwing. We make all of our vases and limited edition vessels, like our Food52 collabs, on the pottery wheel. In this forming method soft clay is wedged (like kneading dough) and then through hand pressure and centrifugal force from the pottery wheel it is formed into a vessel.

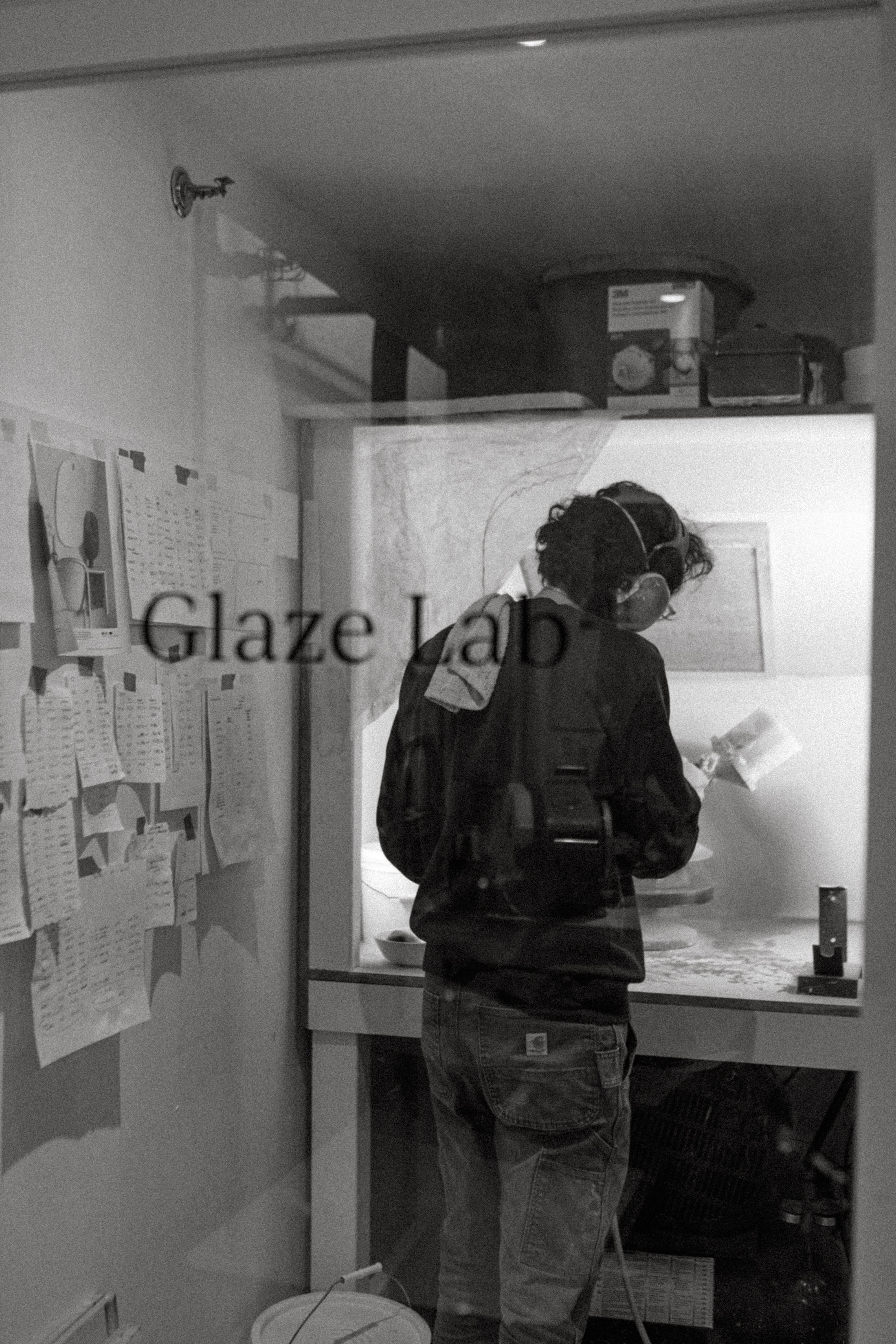

Glaze

The final step in our ceramic creation process is glazing. Glaze is like a thin coating of glass, so to speak, that creates the colors and visual textures of our ceramics. We make all of our glazes in-house from our own recipes that we sample and test countless times (top photos below). Eric is our glaze master. He makes all of our glazes and also applies it to our wares. Glaze is applied to bisqueware which is raw porcelain that is half cooked (so to speak). We either dip pieces in buckets of glaze or spray glaze on to a piece as you can see in the bottom two photos below. Each plate is individually sprayed with a specifically calculated amount of glaze both front and back. Then we load all glazed wares in to our kilns.

Myrth Shop

Our retail shop, Myrth Shop resides in the front area of our studio. This street side store front is a warm, modern home setting where you can see our products in their element and where we can share joy and inspiration with you as you touch and feel all of our products in person.

Thanks so much for taking our virtual tour! We’d love to have you visit us IRL at the Shop. If you are not local we of course have our webshop, and we offer virtual shopping appointments in our shop if you’d like to get a closer look at our products.